5 Ways To Improve Electrical Safety Within Installations

Whether you are completing work for a complex engineering project or repairing a faulty wire, electrical installations are a fundamental part of any project. No matter what job you are completing, electricity will always be dangerous to work with. If not dealt with correctly, there can be serious, even fatal consequences.

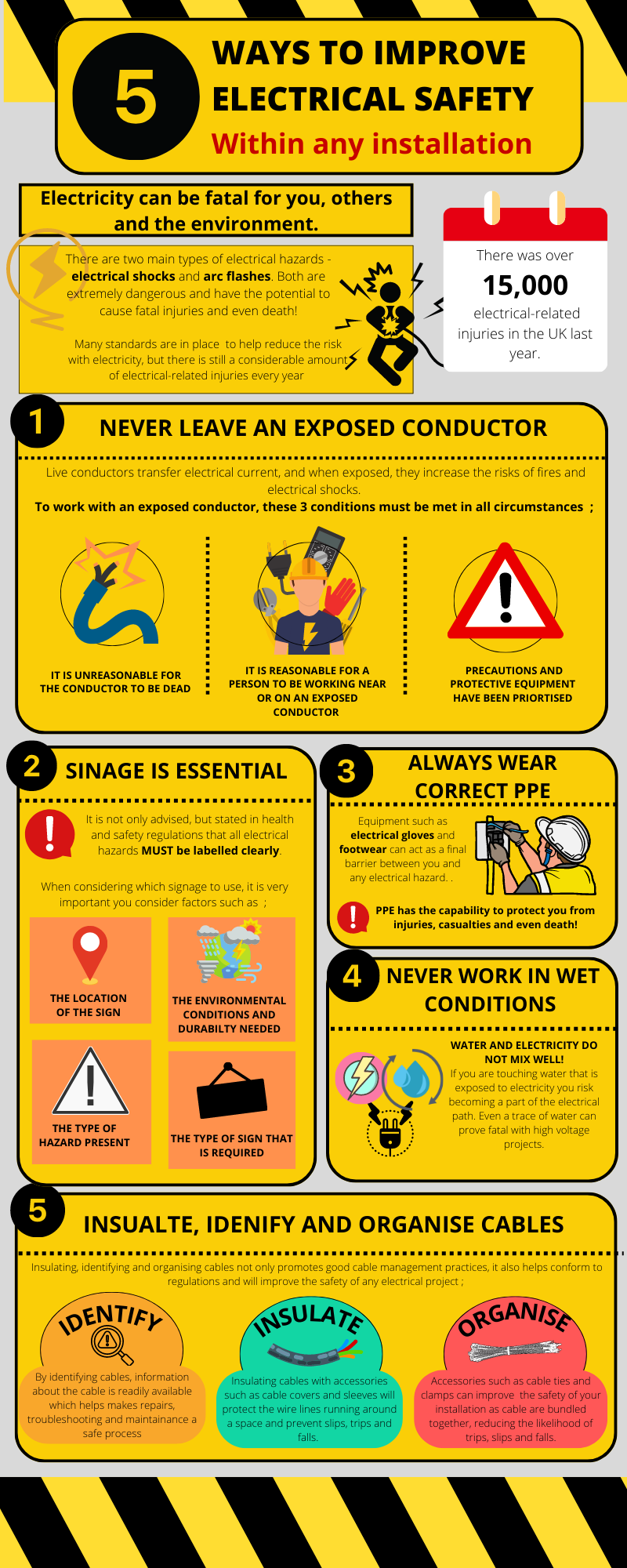

When it comes to electrical safety there are two main types of hazards – electrical shocks and arc flashes. Both are extremely dangerous and have the potential to cause serious injuries to individuals.

Electrical shocks occur when electrical current flows through your body. It can have devastating effects, causing burns, muscle damage, cardiac arrest and even death. In comparison, arc flashes are a type of electrical explosion that results from electrical current becoming uncontrolled and passing through an air gap between conductors. Similarly, this has dangerous effects, including severe burns, blindness and hearing loss.

To avoid electrical hazards, the appropriate standards and regulations must be followed to reduce the risk of injuries. However, there are still a considerable number of electrical-related injuries every year. This is highlighted by statistics from the HSE, who reported over 15,000 electrical-related injuries in the UK between 2020-2021. In response to this, there is now a greater focus on following a detailed and attentive electrical plan. Standards, such as the IEE Wiring Regulations, are regularly updated to include additional practices that aim to reduce electrical injuries, taking into consideration every potential electrical hazard.

To help you reduce your electrical risks, here are five ways to help improve safety within your installation:

1. Never Leave an Exposed Conductor

Exposed conductors should be taken very, very seriously. Live conductors transfer electrical current, and when exposed, they increase the risks of fires and electrical shocks. A high draw of power from an exposed conductor can also mean the circuit may trip and cause a complete failure of your electrical system.

It is stated in Section 14 of the Electricity at Work Regulations 1989 (EAWR) that working on an exposed conductor is only permissible if three conditions are met:

- It is unreasonable in all circumstances for the conductor to be dead

- It is reasonable in all circumstances for an individual to be at work on or near it while it is live

- Suitable precautions including, where necessary, the provision of protective equipment has been taken to prevent injury.

It is important to note that if just one of these conditions cannot be met, live working cannot be permitted.

Therefore, it is very important for an individual to understand the hazards of the system and equipment, the level of supervision necessary, the precautions that have to be taken and the system of work needing to be employed.

2. Always Wear the Correct Personal Protective Equipment

Personal protective equipment (PPE) is specified for a wide variety of situations, particularly within the past few years. However, it is extremely important when electricity is involved.

When it comes to electrical shocks, safe working practices such as isolation, locking off isolators and installing grounding links will provide primary barriers to electrical hazards. However, PPE equipment is also essential as it is the final barrier that will protect you and therefore has the capability of preventing injuries, casualties and even deaths.

Appropriate PPE may vary with each electrical project and will be dependent on the type of application you are involved in. However, it is recommended to wear electrically insulated gloves and footwear when dealing with any sort of electricity as the insulation will act as a vital barrier from electrical shocks.

Additionally, if you are working with wiring or are in close contact with any electrical current, it is advised you wear a face-shield, eye protection and a fire-resistant helmet to ensure risk levels are minimised.

3. Signage is Essential

In any installation, there is the potential for electrical hazards on site; whether it is working near overhead power lines or with high voltage electrical equipment, all electrical systems have safety risks to both people and the environment that they are in. Therefore, engineers or anyone involved in the project have a responsibility to report any safety hazards they identify. the Heath and Safety Regulations demand that any electrical hazard must be labelled clearly. Signage must be located in a position that makes clear where the hazard lies and it that it cannot be inadvertently missed by personnel. The sign material must also be considered to ensure it is durable enough to withstand the environmental conditions. Temperatures, UV Exposure, Chemicals and abrasion are all factors affecting signage durability, therefore it is important you choose a sign that can withstand these conditions. For example, Acrylic signage is generally weather resistant, however if you require a sign that has resistance to the harshest environments, stainless steel may be more appropriate.

4. Never Work in Wet Conditions

It is universally accepted that water and electricity do not mix well, but it does no harm to be reminded of this. Water is usually an excellent conductor of electricity. If you are in contact with water that is exposed to electricity you risk becoming a part of the electrical path. Even a trace of moisture can prove fatal with high voltage projects.

If you are working in any sort of electrical project, the presence of water can dramatically increase the chance of electrocution. Unless specifically designed to do so, electrical equipment should not be used near a source of water or operated with wet hands. If equipment is inadvertently exposed to water, it must be inspected by a qualified electrician before being used again to ensure workers’ safety. Eliminating wet conditions should be a staple component of any electrical plan.

5. Insulate, Identify and Organise Cables

The insulation, identification and organisation of cables and wires is a critical process of any electrical project

It is essential for the safe long-term maintenance and upgrading of an installation over it's lifespan and decommissioning. Well-planned cable management facilitates future modifications and helps to prevent worker injury. By labelling, marking and organising wiring to a high standard, engineers can dramatically improve safety.

If information about every cable is clearly marked at all terminations and along cable runs then maintenance, troubleshooting and repairing an installation becomes a much more straightforward process. Securing cables appropriately with Cable Ties

, Cable Clips, and Cable Clamps minimises the risks of physical damage and the associated electrical safety risks to personnel. Large conductors must be fixed using an appropriate cable cleat system with careful consideration of the kinetic forces that could be induced in the cables due to a short circuit situation.

In any electrical project, safety needs to be a main priority. These five tips are only a glimpse into what is involved in ensuring safety within installations. If you need any more information about the type of products you need or if you are still unsure on how to implement best practices to improve electrical safety we’re here to help! Simply Contact us below and we’ll be happy to assist you. Or, alternatively, you can browse our store for the associated products.