Cable Ties - What are the different types and how do I select the kind I need?

Read time: 6 minutes

Welcome to your comprehensive guide to one of the unsung heroes of the electrical and organisational world — the humble cable tie.

Whether you're an experienced electrical engineer, a DIY enthusiast, or simply someone curious about the myriad of uses of different cable tie types, this article is for you. We'll unravel the mysteries behind these versatile tools, exploring their materials, applications, and the nuances that make one type more suited for a task than another. So, strap in to the world of cable ties, where we'll answer all the questions you didn't even know you had.

Cable Tie Basics

What's the difference between a zip tie and cable tie?

There is no difference between zip ties and cable ties. Cable ties and zip ties are the same thing. Both terms describe the same fastening tool used for securing wires and cables. Cable ties are crucial for electrical engineers, offering adjustable, secure bundling to meet diverse tensile and environmental requirements.

What are cable ties used for?

Cable ties are primarily used for bundling and securing cables and wires to maintain tidy and safe installations. They are useful in electrical setups, data centres, and for organising cables in both industrial and domestic environments. Available in various materials and sizes, cable ties offer a reliable solution for managing cables efficiently.

How many types of cable ties are there?

There are numerous types of cable ties, including standard nylon, in-line cable ties, releasable zip ties, stainless steel, polypropylene, and specialised plastics such as TEFZEL, HALAR Fluoropolymer, and Polyetheretherketone (PEEK). Each different type of zip tie is designed for specific environmental and strength requirements, with a range of widths and lengths available to accommodate diverse cable management needs.

How does a cable tie work?

A cable tie works by threading the tail end through a ratchet mechanism in the head, which allows for one-way movement, securing the tie as it's pulled tighter. The design prevents the tie from loosening, ensuring a stable and secure bundling of cables or objects.

What is the most common cable tie?

The most common type of cable tie is the standard nylon tie, favoured for its versatility, durability, and cost-effectiveness. Suitable for a wide range of applications, these ties are available in various lengths and tensile strengths, making them a staple in cable management tasks.

What are nylon cable ties used for?

Nylon cable ties are widely used for bundling and securing cables, wires, and other items in electrical installations, networking, and general organisation tasks. Their flexibility, strength, and resistance to environmental factors make them ideal for both indoor and outdoor applications (when using weather resistant ties).

What is an alternative to cable ties?

As an alternative to cable ties, cable clips and clamps are excellent for securing cables, offering a more permanent and structured solution. They are particularly suitable for routing cables along surfaces or within enclosures, providing easy access and organisation.

Do cable ties damage cables?

If over-tightened, cable ties can potentially damage cables by pinching insulation or exerting excessive pressure on the wires, leading to impaired functionality or safety risks. Using the correct size and tension, possibly with tensioning tools, helps prevent damage and ensures secure, safe cable management.

Cable Tie Usage

How do you tension a cable tie?

To tension a cable tie, insert the tail end into the head and pull tightly to secure the bundle. For precise tensioning and to ensure the tie is not overly tightened, causing damage, use a cable tie tensioning tool. This tool allows for adjustable tensioning, providing a secure yet safe installation.

How tight should cable ties be?

Cable ties should be tightened enough to secure cables without over-tightening and potentially damaging them. Using proper cable tie tensioning tools ensures the correct tension, maintaining safety and organisation while preventing wire insulation damage, and allowing for slight cable movement.

Can you join two cable ties together?

Yes, joining two cable ties together to extend their length is possible, by inserting the tail of one tie into the head of another. However, we offer cable ties in various lengths to accommodate different needs, providing a more straightforward solution for securing larger bundles or objects.

Can you join metal cable ties together?

Joining metal cable ties together is not typically recommended due to their design and material properties. Metal ties are engineered for strength and durability in single lengths. For applications requiring longer ties, it's advisable to select a metal tie of the appropriate length to ensure maximum performance and security.

Can you undo a cable tie without cutting it?

Standard cable ties are designed for one-time use and typically require cutting to be removed. However, releasable cable ties feature a mechanism that allows them to be undone without cutting, making them reusable for applications where adjustments or removal might be necessary.

Cable Tie Materials

Why are cable ties so strong?

Cable ties are strong due to their high-quality materials, like nylon or stainless steel, and their locking mechanism that allows for tight, non-slip bundling. This combination provides durable tensile strength, ensuring secure fastening for a wide range of applications.

What are the strongest cable ties?

The strongest cable ties are made from stainless steel, offering exceptional tensile strength and durability. Designed to withstand harsh conditions, including extreme temperatures, chemicals, and UV exposure, stainless steel ties are ideal for demanding applications where maximum strength and reliability are essential.

Can cable ties be used outdoors?

Cable ties can be used outdoors, provided you select the appropriate type. UV-resistant and weather-resistant cable ties are made to endure sunlight, weathering, and temperature changes, ensuring they remain durable and functional in external environments for extended periods.

Are cable ties UV resistant?

Not all cable ties are UV resistant. Standard cable ties may degrade under sunlight. However, there are cable ties specifically designed to be

UV resistant, made from materials that can withstand prolonged exposure to ultraviolet light, making them suitable for outdoor applications without quickly deteriorating.

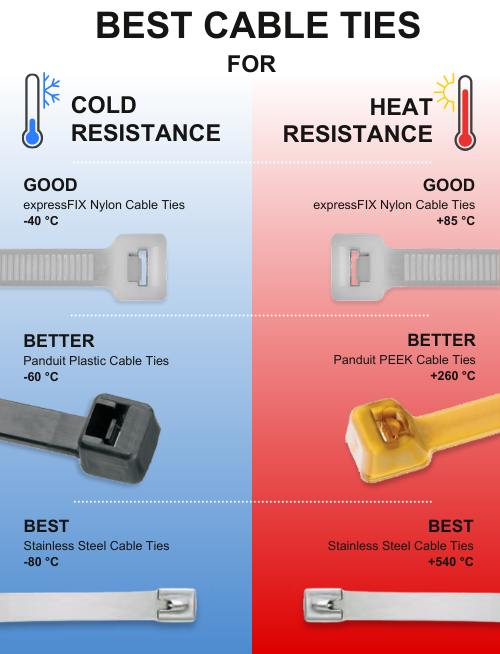

What temperature can cable ties withstand?

The temperature tolerance of cable ties varies by material. Standard nylon zip ties manage -40°C to 85°C, while Panduit's Polyetheretherketone PEEK cable ties withstand temperatures up to 260°C (500°F). Stainless steel cable ties can take up to 540°C (1004°F).

To match the right cable tie to your needs consult our chart below.

Do zip ties break in cold weather?

Standard zip ties can withstand cold temperatures down to -40°C before becoming brittle or prone to breakage. However,

Panduit weather resistant cable ties are more cold-resistant, functioning down to

-60°C (-76°F). For extreme conditions,

stainless steel cable ties are recommended, as they are

cold resistant to -80°C, providing superior durability and performance.

How do you secure outdoor cables?

To secure outdoor cables, use UV and weather-resistant cable ties or stainless steel ties for durability against the elements. Additionally, consider using cable clips and/or clamps for stable routing along structures. Ensure ties are snug but not overly tight to prevent damage to the cable insulation, using a cable tie tensioning tool.

What’s the difference between black and white cable ties?

White or natural coloured cable ties are designed for indoor or short-term use, lacking outdoor durability. Black cable ties, potentially heat and/or UV resistant, are better for outdoor settings. Yet, it's vital to verify their specifications, as not all black ties guarantee this resistance.

Why are UV resistant zip ties black?

UV resistant zip ties are often black due to the addition of carbon black, a stabiliser that enhances their resistance to ultraviolet light. This makes them more durable and suitable for outdoor use, as the carbon black helps prevent degradation from sunlight exposure.

What are metal detectable cable ties used for?

Metal detectable cable ties are used in industries where contamination prevention is critical, such as food processing and pharmaceuticals. Their metal content allows for easy detection by safety scanners, reducing the risk of contamination by ensuring any accidentally incorporated ties can be swiftly identified and removed.

How are metal detectable zip ties made?

Metal detectable zip ties are manufactured by incorporating a metal powder, often stainless steel or another detectable material, into the nylon or plastic during the production process. This integration allows the ties to be detected by metal scanning equipment, making them ideal for use in sensitive environments like food processing and pharmaceuticals, where contamination control is paramount.

Panduit Plastic Cable Tie Comparison Chart

Find the right cable tie based on colour, material, style, heat, UV, chemical and flame resistance.

🔎 Looking for something not on our website?

- Browse the Panduit Cable Ties Catalogue or our expressFIX Catalogue to view a wider selection of product.

- Email us at sales@expresselectrical.co.uk with quantities and part numbers for a quote!